The twin-screw sandwich extrusion molding technique offers several innovative features that enhance the production of layered food products. One key aspect is the ability of the twin-screw system to not only extrude material from two separate cylinders but also incorporate a unique single-turn, variable-diameter, and variable-pitch double-disc design. This configuration allows for better control over material flow, shaping, and forming, making it an excellent example of how screw technology can be applied in epitaxial or layered manufacturing processes.

Additionally, the parallel sandwich extrusion method—where the inner filling is introduced between the two outer layers—demonstrates a clever design approach. This method has provided valuable insights for later developments in multi-cylinder systems, particularly in the design of parallel casting mechanisms with floating balls. The concept of layering through controlled extrusion opens up new possibilities for more complex and efficient sandwich structures.

However, this mechanism comes with its challenges. It involves a more intricate transmission system, requiring precise coordination between multiple moving parts. While it excels at producing dough-based products, it is less suitable for semi-fluid or soft materials commonly found in confectionery. These softer materials tend to be more difficult to handle due to their high moisture content, which makes them sticky and hard to shape using traditional extrusion methods.

In contrast, cast-molded forming relies on a plunger or piston to push the material into a mold, often using a combination of a skin and filling. This process is typically carried out with specialized casting devices that allow for more flexibility when working with fluid or semi-fluid ingredients. As seen in the classification of sandwiches, traditional techniques have primarily focused on pasta-based products, while the application of sandwich molding to confectionery items remains underdeveloped.

Because confectionery materials are often softer and contain more water, they require casting rather than extrusion. This presents higher demands on the structural design of the casting equipment, as the system must prevent sticking and ensure even distribution of the material. The casting method not only serves as an effective solution for these types of materials but also provides inspiration for future innovations in sandwich formation and molding technology. Overall, these different approaches highlight the importance of adapting machinery and techniques to suit the specific characteristics of the materials being processed.

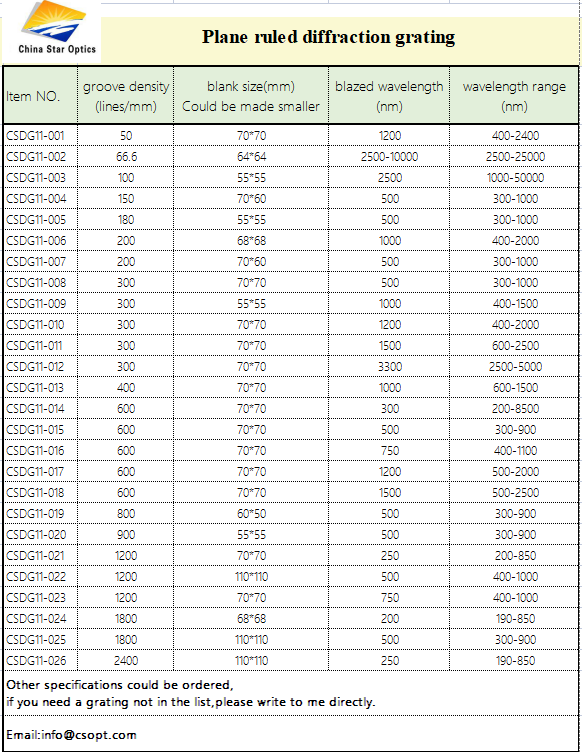

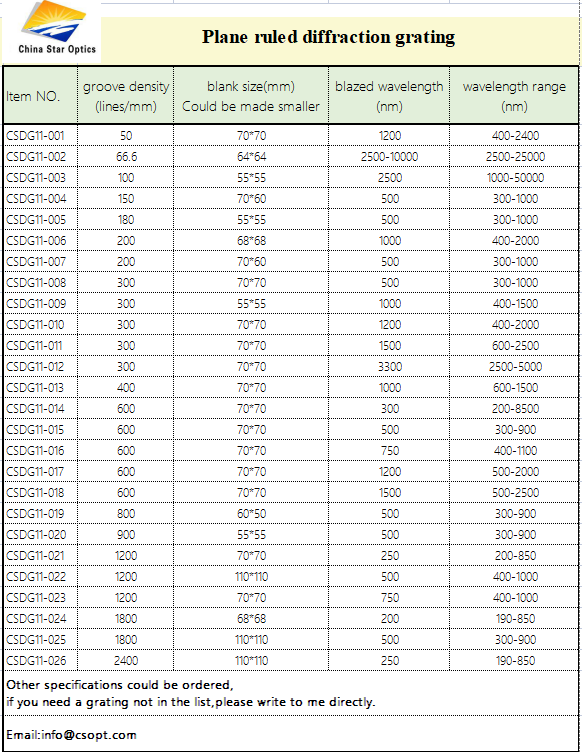

Plane Ruled Grating

Plane ruled gratings are characterized by a superior efficiency at their design wavelength compared with holographic gratings. Plane Ruled gratings comprise the majority of diffraction gratings used in spectroscopic instrumentation and are especially useful in systems requiring high resolution.Â

China star optics can provide customers with a variety of replicated grating products such as diffraction gratings, reflective gratings,holographic gratings,concave gratings etc. to meet different needs. Maximum ruled area is up to 300 x 300 mm for plane ruled diffraction gratings. For replicated diffraction and transmission gratings the ruling density can be from 20 grooves per millimeter to 2400 grooves per millimeter, wavelength from 0.2 micron to 25 microns.Â

Holographic gratings:

Specifications:

Ruled area: <=70 * 70mmÂ

Wavelength range: 0.2-0.8umÂ

Grooves per mm: 1,200 to 3,600L/mm

Diffraction: >70%Â

Ruled gratings:

Specifications:

Ruled area: <=70 * 70mmÂ

Wavelength range: 0.2-15umÂ

Grooves per mm: 50 to 2,400L/mmÂ

Diffraction: >70%

Concave gratings:

Specifications:

Ruled area: <=70 * 70mmÂ

Wavelength range: 200 to 900umÂ

Grooves per mm: 490 to 1,200L/mmÂ

Diffraction: >70%

Plane Ruled Grating,Plane Ruled Diffraction Grating,Plane Reflection Grating,Plane Ruled Reflective Grating

China Star Optics Technology Co.,Ltd. , https://www.csoptlens.com