Sulfuric Acid: Which Fastener Material is Best?

Sulfuric acid (Hâ‚‚SOâ‚„) is one of the most critical and widely utilized acids, playing an indispensable role across numerous industries. Selecting the appropriate material capable of withstanding this aggressive environment is equally crucial. This newsletter aims to explore the various material options suitable for such demanding conditions.

**WHICH MATERIAL IS THE BEST?**

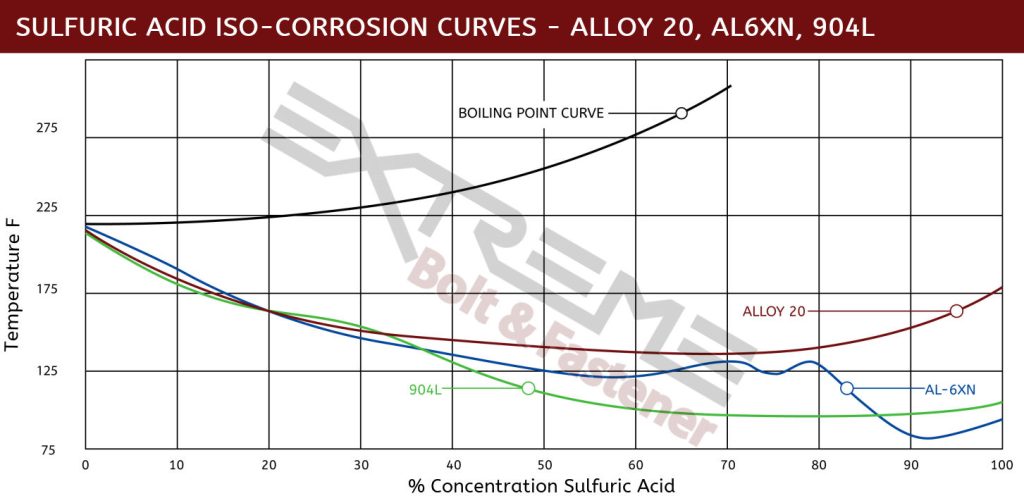

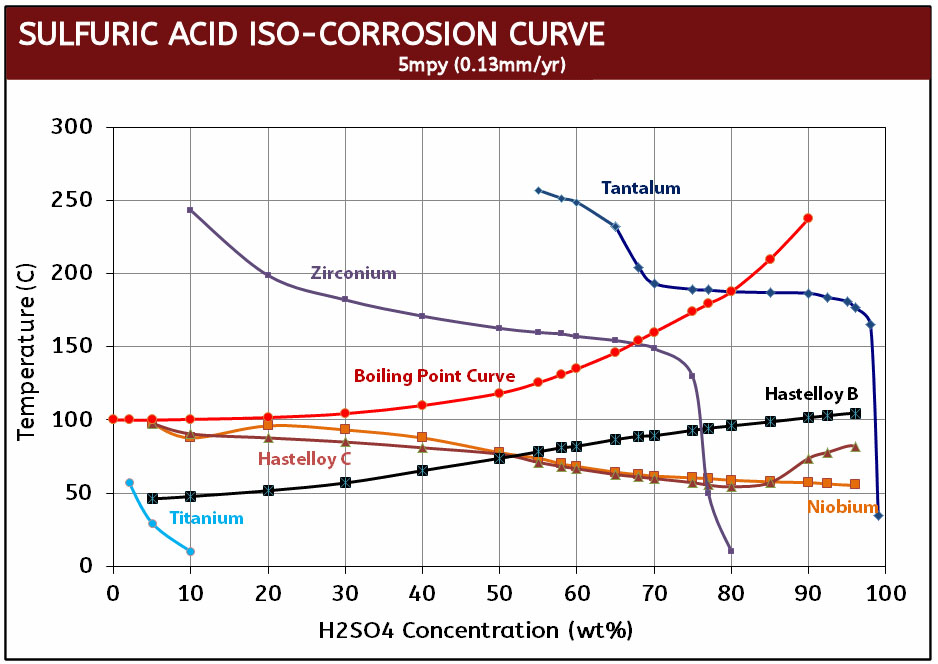

The answer depends on both the concentration and temperature of the sulfuric acid together. When evaluating corrosion resistance, the interplay between temperature and chemical concentration is always significant. You cannot focus solely on one parameter while ignoring the other. Generally, when the concentration of sulfuric acid is high, the temperature range within which a material can operate safely tends to decrease, and vice versa—higher temperatures often require lower concentrations to prevent corrosion. However, several materials exhibit impressive resilience even under extreme conditions.

**ALLOY 20 BOLTS**

For basic high-temperature resistance, Alloy 20 bolts are worth considering. They perform exceptionally well in environments with 20-40% boiling sulfuric acid.

**HASTELLOY**

While Hastelloy cannot withstand boiling sulfuric acid, it remains a viable option for handling high concentrations of sulfuric acid at temperatures typically below ~135°F.

**ZIRCONIUM**

Zirconium stands out as an excellent choice for high-temperature sulfuric acid applications, capable of enduring up to 300°F and concentrations as high as 70%. However, caution is advised since zirconium bolts can corrode easily if exposed to even trace amounts of oxidizers.

**TANTALUM**

Tantalum represents the pinnacle of corrosion resistance against sulfuric acid. Although it comes at a steep cost, tantalum bolts are reserved for the most severe services. They exhibit virtually no corrosion rate for all concentrations up to 98% at temperatures up to 350°F.

**HIGH-STRENGTH OPTIONS**

- **Hastelloy Screws**: These bolts not only excel in high-temperature and high-concentration environments but also boast a tensile strength of up to 100 ksi.

- **Inconel 625**: Providing slightly less corrosion resistance than Hastelloy, Inconel bolts offer a higher tensile strength of 144 ksi.

**POLYMERS FOR Hâ‚‚SOâ‚„**

- **PTFE and PFA**: These polymers provide the highest level of corrosion resistance among plastics but lack in mechanical strength.

- **PEEK Screws**: Combining good corrosion resistance with high strength, PEEK bolts are an excellent choice for demanding sulfuric acid environments.

**CERAMICS**

Ceramics are another option, capable of withstanding temperatures up to 4000°F and resisting most chemicals, including sulfuric acid. While they excel in handling high temperatures and concentrations, ceramics lack strength and can be brittle, making them suitable only under specific conditions.

In conclusion, the choice of material depends heavily on the specific requirements of your application. Whether you prioritize corrosion resistance, strength, or temperature tolerance, there is a material tailored to meet those needs. Always consider the full spectrum of operating conditions before finalizing your selection.

Diaphragm Fiber Fabric Air Duct

Diaphragm Fiber Fabric Air Duct,Insulation Air Duct,Central Ac Duct,Pvc Air Duct Fabric

Jiangsu Buna Technology Development Co. , Ltd. , https://www.bunaduct.com