Type of environmental pollution

In the context of environmental issues, air pollution remains one of the most pressing challenges in China. According to the "China Environmental Bulletin," it was reported that in 1997, urban air quality across the country remained at a high level of pollution, with northern cities experiencing more severe conditions than their southern counterparts (refer to Figure 3-1). The annual average concentration of sulfur dioxide ranged from 3 to 248 micrograms per cubic meter, while the national average stood at 66 micrograms per cubic meter. More than half of the cities exceeded the national secondary standard for sulfur dioxide, which is set at 60 micrograms per cubic meter. In particular, northern cities had an annual average of 72 micrograms per cubic meter, while southern cities averaged around 60 micrograms per cubic meter.

Cities located in the southwest, such as Yibin, Guiyang, and Chongqing—regions known for their high-sulfur coal usage—and cities with heavy energy consumption, including those in Shanxi, Shandong, Hebei, Liaoning, Inner Mongolia, Henan, and parts of Shaanxi, faced particularly severe sulfur dioxide pollution.

The primary sources of this pollution include energy use. As China's economy grew rapidly and living standards improved, energy demand surged. This increase in energy consumption led to a sharp rise in sulfur dioxide emissions, which became a key factor behind the longest and most damaging acid rain events in the Southwest region.

Additionally, motor vehicle exhaust has become a major contributor to urban air pollution. Over recent years, the number of vehicles in major Chinese cities has risen significantly, making vehicle emissions a critical source of pollutants. Alongside carbon monoxide and nitrogen oxides, lead emissions from automobiles also play a significant role in degrading urban air quality.

Environmental protection involves the conscious efforts of humans to safeguard natural resources and use them responsibly, preventing the degradation and pollution of the environment. It encompasses comprehensive management of polluted areas to create a healthier living and working environment for people. Environmental protection refers to all actions taken by society to address current or potential environmental problems, balance human activities with nature, and ensure sustainable economic and social development. These efforts include engineering solutions, administrative measures, legal frameworks, economic incentives, public awareness campaigns, and educational programs.

Wind Energy Fasteners Supplier China, Yokelink

sales@yokelink.com

Yokelink has been supplying fasteners for the wind energy industry for over 10 years. These fasteners are utilised in producing a gearbox, a valuable wind mill turbine component located within the nacelle. we also offer standard wind power energy fasteners in line with ISO or DIN, including vibration-resistant security products. Wind tower bolt plays a important role as joining components in fastening different parts of wind turbine tower, Yokelink is a professional manufacturer which supplies high grades fasteners 8.8-12.9 for wind tower projects.

Product Ranges:

We currently service all aspects of the wind turbine market, Our extensive range allows wind

turbine manufacturers to 'single source'all their fastener requirements with all the advantages that this brings, providing a range of fasteners, both standard and customer bespoke for:

turbine manufacturers to 'single source'all their fastener requirements with all the advantages that this brings, providing a range of fasteners, both standard and customer bespoke for:

â—Foundation

â—Tower Construction

â—Blade to Hub

â—Nacelles

â—Off-shore Transition Pieces

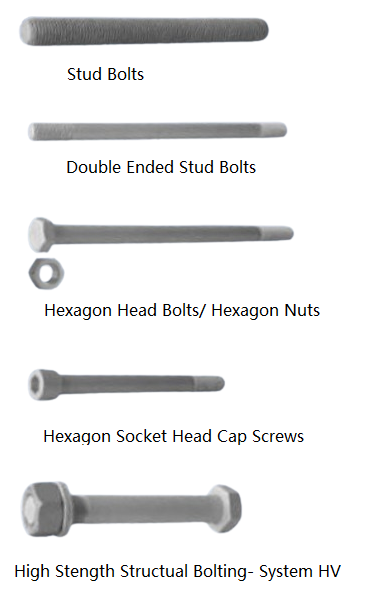

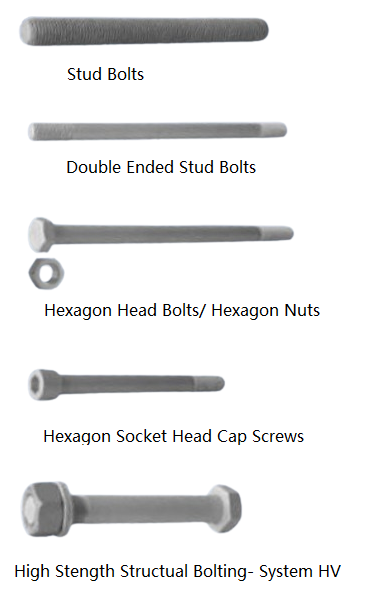

Hex cap screws DIN 931, DIN 933 and ISO 4017

Hex Bolts and Nuts, size M10-M64

Stud Bolts size M12-M64

Threaded Rods size M10-M64

Tower Flange Bolts size M10-M64

WHAT ARE WINDMILL POWER FASTENERS?

WHAT ARE WINDMILL POWER FASTENERS?

Fasteners used in wind power tower and blade connection and transmission, including hex bolts, stud bolts, tower flange bolts, foundation bolts, threaded rods, high strength double head screw, hardened and structural bolts, nuts, washers and threaded rods, and hex cap screws etc.

WHAT'S THE CHARACTERISTICS OF WIND POWER FASTENERS

High strength, high grade and precision, can work in hard conditions like extremely hot and cold environment and corrosion resisted .In wind turbine generator system, because of the randomness of power source, hardness of operating circumstances, special producing and installing, as well as high costs of maintaining, the requirements for wind turbine bolts would be extremely high. We have to take effective actions to ensure the reliability of the bolts connection, from the bolts structure design, manufacture process to production and assembling.

WHAT BOLTS ARE USED IN A WIND TURBINE?

Wind turbine bolts, there are wind turbine blade bolts, wind turbine anchor bolts, wind turbine foundation bolts, high strength and high tension hexagon head bolts, nuts and washers are mainly used for wind turbine.

HOW MANY BOLTS ARE IN A WIND TURBINE?

A most common 3 blades wind turbine requires almost 25,000pcs fasteners. With the rapid increase of wind energy demand in the worldwide, the fasteners for wind turbine and energy increased greatly as well. Most high strength bolts used for wind turbine are grade 10.8, grade 12.9 and the coatings are also very crucial, Dacromet are most commonly coating in wind turbine fasteners.

A most common 3 blades wind turbine requires almost 25,000pcs fasteners. With the rapid increase of wind energy demand in the worldwide, the fasteners for wind turbine and energy increased greatly as well. Most high strength bolts used for wind turbine are grade 10.8, grade 12.9 and the coatings are also very crucial, Dacromet are most commonly coating in wind turbine fasteners.

When you need Wind Power Fasteners, refer to above our catalog. We offer them in a full selection of sizes, provide the diameter or part number to get a quote of wind power fasteners, leave your message, or send us an email. You can also call us to get answers to your questions and place your order.

Wind Energy Fasteners Supplier China, Yokelink

sales@yokelink.com

Wind mill ,Wind Power fasteners, Wind mill Turbine, Stud Bolt, windmill energy, house wind turbine, Wind Turbine Blades

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com